According to the Alliance of Automobile Manufacturers, about 95% of vehicles retired from U.S. roadways are recycled every year. Your online registration renewal company, eTags, found out almost every part of a car can be recycled. The most popular ones are tires, windshield, batteries, steel, iron, radiators, transmissions, car seats, seat belts, oil filters, and even mats.

Use eTags© to Quickly Complete Your DMV Service. Renewals, Title Transfers and More, All Online!

Recycled tires are used to pave roadways. They’re also recycled into playground surfaces, running tracks and equestrian footings. Recycled glass turns into tile flooring, glass beads, porcelain, countertops, and jewelry. If a ton of glass is recycled that saves 10 gallons of oil to produce new glass.

When it comes to steel, more than 18 million tons of this metal is melted and reused, reducing water pollution by 76% and air pollution by 86%. The steel industry saves enough energy to power about 18 million households every year. Recycling metal also uses about 74 percent less energy than making metal.

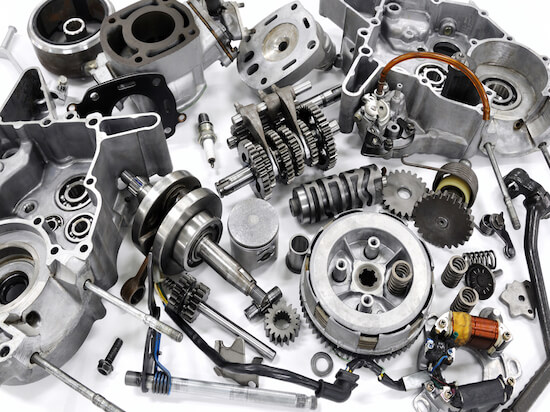

Over 12 million vehicles are recycled in the U.S. annually, with another 8 million in Europe. So how does car recycling work? When a vehicle can’t run anymore, it typically ends up in a junk yard or a recycling facility. In fact, there’s even a certification for automotive recyclers (CAR) that ensures environmentally-friendly standards are respected. Then it’s dismantled and recycled. Fluids, from anti-freeze to brake lubricants, are drained. Hazardous liquids are disposed safely.

Next, the car’s engine and transmission are lifted from the chassis so operators can remove and clean usable car parts. The recovered parts are sold. Whatever is left, including different metals that can’t be recycled are crushed and shredded into a small, metal chunk transported to a steel mill.

And that’s how car parts are recycled!